What is a Decanter Centrifuge? Working Principle, Types, and Applications

2025-05-14

Introduction

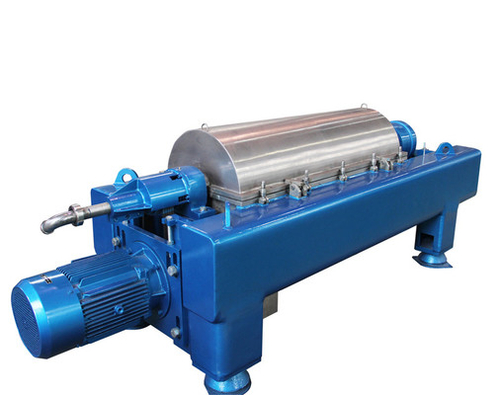

A decanter centrifuge is an industrial machine that separates solids from liquids (or two immiscible liquids) using high-speed rotational force. Widely used in wastewater treatment, food processing, and oil drilling, it operates continuously.

How Does a Decanter Centrifuge Work?

The working principle of a decanter centrifuge is to achieve solid-liquid separation through centrifugal force generated by high-speed rotation. The slurry to be processed enters the rotating bowl (typically at 1,500 to 4,000 RPM) through a central feed pipe. Under the effect of centrifugal force, the heavier solid particles quickly move outward and settle along the bowl wall, forming an outer layer, while the less dense liquid forms an inner layer. At the same time, a scroll conveyor rotates at a slightly slower speed (5 to 20 RPM less than the bowl) to continuously transport the settled solids toward the conical end of the bowl for discharge. The clarified liquid is discharged through adjustable weirs, enabling continuous solid-liquid separation.

Different Types of Decanter Centrifuges

Decanter centrifuges come in several types, each designed to suit specific applications and material properties. Here are the main types:

Two-Phase Decanter Centrifuge

The two-phase decanter centrifuge is designed for separating solid particles from liquids in mixtures where the composition includes a distinct solid-liquid ratio and a uniform liquid phase.

In operation, the material flows into a horizontally oriented drum that spins at high speed. Due to the centrifugal force generated, the denser solid particles are driven outward to the inner wall of the drum, while the lighter liquid remains closer to the center. A helical screw conveyor,

rotating at a slightly reduced speed compared to the drum, steadily transports the accumulated solids toward the conical end for removal. At the same time, the clarified liquid exits continuously from the opposite end via adjustable weir plates.

This type of centrifuge is widely applied in fields such as municipal sludge treatment, industrial wastewater processing, food industry separation tasks (e.g., removing solids from soy milk), and the handling of drilling fluids in the energy sector.

Three-Phase Decanter Centrifuge

The three-phase decanter centrifuge is designed to simultaneously separate solids and two immiscible liquid phases—commonly oil and water—from complex mixtures that contain fat, oil, or emulsified substances.

When the feed material enters the high-speed rotating drum, centrifugal force causes the components to separate based on their densities. The heaviest solid particles move outward and settle against the drum wall. Just inside this layer, the denser liquid (typically water) forms a middle layer, while the lightest liquid (such as oil) forms the innermost layer near the rotation axis.

A scroll conveyor rotating slightly slower than the drum transports the solid fraction to the conical end for discharge. Meanwhile, the two liquid layers are directed to separate outlets or adjustable weirs positioned at different radial levels, allowing for independent and continuous extraction of each phase.

This type of centrifuge is widely used in sectors such as food processing (e.g., vegetable oil or animal fat extraction), meat by-product recovery, oil-water-solid separation in the petroleum and energy industries, and in the treatment of complex industrial waste liquids like emulsions.

Decanter Centrifuge Applications

Decanter centrifuges are widely used across various industries due to their ability to continuously and efficiently separate solids from liquids.

In the environmental sector, they are essential for municipal and industrial wastewater treatment, particularly in sludge dewatering.

In the oil and gas industry, they are used to treat drilling mud and separate oil, water, and solids.

The food and beverage industry relies on them for applications such as juice clarification, soy milk residue separation, and the extraction of vegetable oils and animal fats.

In meat processing and by-product recovery, decanter centrifuges help separate solids, fats, and water, improving resource utilization.

They are also employed in the chemical and pharmaceutical industries for separating crystallized compounds, recovering reaction products, and purifying solutions.

In mining and metallurgy, these machines are used for tailings management, dewatering slurry, and recovering valuable minerals.

Additionally, in the pulp and textile industries, decanter centrifuges assist in reclaiming fibers and removing solids from process water.

Their versatility, automation, and high throughput make them an indispensable solution for solid-liquid separation across a wide range of industrial processes.

Need a Custom Decanter Solution for Your Career?

We focus on high-solid and high-corrosion separation systems. If you have any questions, please contact us in time.

Read More

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!