Description

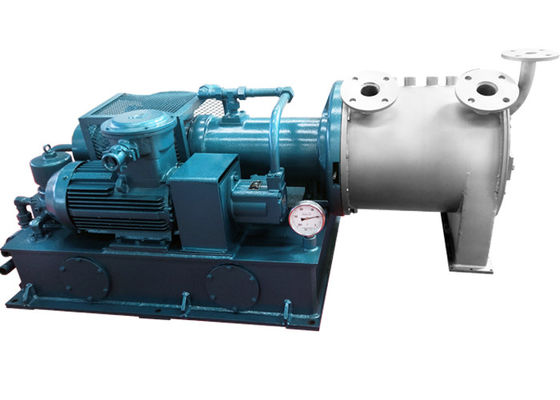

PP series Two-stage Pusher Centrifuge is a kind of perforated basket centrifuge, both continuous and effective.

The mixture to be separated is fed through the feeding pipe and the distributor continuously and evenly into the first stage basket. Most of the mother-liquor in the feed, acted on by centrifugal force, departs through the sieves into the liquor-collecting casing where it will be discharged out of the machine.

The first stage basket rotates and reciprocate, pushing the formed product cake into the second stage basket .The cake can have sufficient retardation in the centrifuge with being acted on by more centrifugal force, and therefore, the desired humidity of the cake can be guaranteed.

Afterwards, the cake is continuously discharged out of the basket. In case of high purity for the solid product, the effective washing can be carried out in the centrifuge. If necessary, the washing agent and the mother-liquor can be discharged separately.

It is suitable for the material with solid content 40-60%,particle size larger than 0.15mm,widely used in the mineral salt ,sea salt and chemical field as CuSO4.5H2O,etc.

![]()

Advantages

1.Big capacity with full automatic operation

2.Low moisture in the cake after separation

3.Robster material to resit the corrosion,DSS material will be used as optional

4.SKF bearing and strong collocation ,with over than 15years working life

5.CE certificate

Technical parameters

|

Model |

PP-40 |

PP-50 |

PP-60 |

|

Basket diameter (mm) |

290/360 |

438/500 |

560/630 |

|

Stroke of pusher mechanism (times/min) |

40-80 |

40-80 |

70-80 |

|

Machine speed (rpm) |

2500 |

2000 |

1360 |

|

Operative oil pressure (Mpa) |

2.5 |

2 |

8 |

|

Motor of oil pump (kw) |

5.5-7.5 |

22 |

13-30 |

|

Main motor (kw) |

11-15 |

37-45 |

55 |

|

Output (t/h) |

5-7 |

12 |

20 |

|

Sieve slot |

To be decided |

||

|

Operation temp. (°C) |

Below 105 |

Below 105 |

Below 105 |

|

Overall dimension (mm) |

2346*1090*1006 |

3660*1420*2078 |

3127*1700*1955 |

|

Weight (kg) |

2600 |

4400 |

4860 |

Pictures on site

![]()

![]()

After-sales

* 12 months guarantee period from machine arriving date.

* Abundant spare parts in stock are availble to provide.

* Our technicians could be dispatched for overseas service.

* 7*24 hours technical consultation.

* Your workers could get trained both in our factory and yours.

* Routine tracing till the machine work properly will be done timely.

* We will remind you to do the normal maintenance.

* Your suggestions or any comments & reflection would be treated in priority.

* Marketing team will visit you during our visit to your country if you require.

Contact us

Zhangjiagang Peony Machinery Co., Ltd

Add: Leyu Developing Zone, Zhangjiagang City, Jiangsu Pro, China.

Web: www.peonyfns.com, www.peonycentrifuge.com, www.separator-centrifuge.com

Tel: 0086 512 56998960/56300801

Fax: 0086 512 58797983

Mobile: 0086 19951199986(WhatsApp)