Brief Introduction

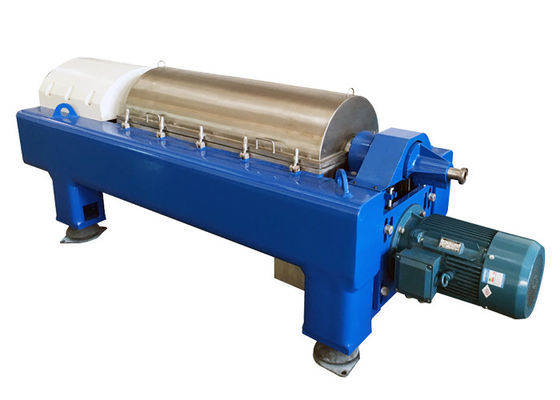

Centrifuge for continuous separation of solids from liquids such as thickening and dewatering sludge, suspensions with granular solids, clarification of liquids, separating starch, etc. We provide a broad range of DECANTER sizes.

![]()

Application

1. Dewatering and thickening of sludge form municipal and industrial waste water, such as :municipal sludge, paper mill sludge, starch sludge, steel mill sludge, printing and dyeing mill sludge, water works sludge, pharmaceutical sludge, PVC sludge, sewage desulfurization sludge,grain stillage, power plant ash sludge, dairy sludge, beer sludge, drilling mud, electroplating liquid, fermented liquid manure, oil refining sludge, soap sludge, leather sludge, and other types of sludge.

2. Chemical or pharmaceutical products such as: butane dicarboxylic acid, alum, aluminum hydroxide, ammonium hydrogen carbonate, ammonium nitrate, ammonium sulphate,anthracene, antibiotics, barium chloride, barium carbonate, barium sulphate, benzene, blood products, blue vitriol, borax, boric acid, calcium carbonate, calcium citrate, calcium hydroxide, calcium nitrate, calcium oxalate, casein, cellulose, chrome yellow, clay, methyl cellulose, corundum, corn plum mule, cooking oil, processed fish, mirabilite, glutamate, hops, pesticide diatomaceous earth, herbicides, tartaric acid, sodium sulphate, sodium phosphate, sodium nitrate, carbon black and others materials.

3. Mineral oil, waste oil, bilge sludge, lubricating oil.

4. recovering of animal and vegetal basic products (oils/fats, starch, proteins)

5. Beverages (wine, beer,fruit)

Technical parameters

| Model | G-force | Capacity(m3/h) | Power(kw) |

| PDC14-3-w | 2600 | 3~15 | 11/30 |

Site picture

![]()

![]()