3 Phase Liquid Solid Separation Decanter Centrifuge , Centrifugal Machine

Description

Tricanter centrifuge, also known as a three-phase decanter centrifuge, is a specialized type of centrifuge used for the separation of three different phases of a mixture. It is commonly employed in industries such as oil and gas, chemical, food processing, and wastewater treatment.

The tricanter centrifuge utilizes the principle of sedimentation and centrifugal force to separate a mixture into three distinct phases: solids, liquid, and liquid. It is particularly effective in applications where the separation of two immiscible liquids and solids is required.

The centrifuge consists of a horizontally arranged cylindrical bowl with a screw conveyor inside. The mixture is fed into the bowl, and due to the high rotational speed, the centrifugal force causes the heavier solids to settle at the bowl wall, forming a sediment layer. The lighter liquid phase forms an intermediate layer, while the second liquid phase, which may have a different density or composition, forms the innermost layer.

The screw conveyor inside the tricanter centrifuge rotates at a different speed than the bowl, which helps to transport the separated solids out of the bowl while simultaneously discharging the separated liquid phases through separate outlets. This allows for continuous and simultaneous separation of the three phases.

Tricanter centrifuges offer several advantages in industrial applications. They provide high separation efficiency, allowing for the recovery of valuable solids or liquids from the mixture. They are also capable of handling a wide range of feed materials with varying solid and liquid concentrations. Additionally, tricanter centrifuges can operate continuously, enabling efficient and uninterrupted processing.

Structural characteristics

Main technical parameters

|

Capacity |

10-15m3/h |

|

|

Drum diameter |

540 mm |

|

|

Drum working length |

2000mm |

|

|

Max rotating speed |

2800 r/min |

|

|

Power |

Main motor |

45kW/50Hz/380V |

|

Auxiliary motor |

15kW/50Hz/380V |

|

|

Net weight |

About 6000 kg |

|

|

Overall dimension (L×W×H) |

4520mm×1250mm×1400mm |

|

|

Loading vibrating intensity |

≤7.1 mm/s |

|

|

Noise |

≤90 dB(A) |

|

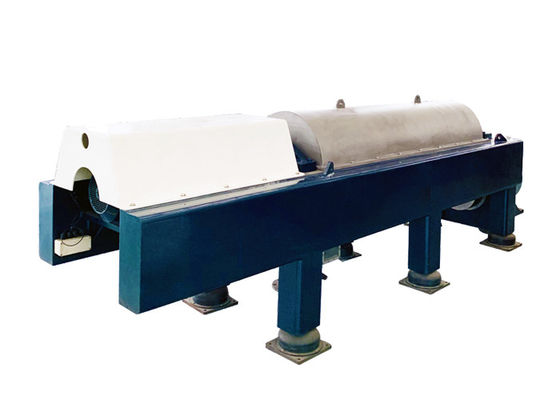

Structure

![]()

1. Auxiliary motor 2. Gear box 3. Hood 4. Bowl and bearing block 5. base 6. Feed pipe 7. Main motor

![]()

Electrical control

Outline drawing and foundation drawing

Outline drawing (1) of 3-phase decanter model PDCS-21

![]()

Outline drawing (2) of 3-p

![]()

Foundation drawing of 3-phase decanter model PDCS-21

![]()

Technical requirement

Foundation height H (600mm-800mm) can be as per the actual requirement, to ensure the solid residue and light liquid can discharge smoothly.

Advantages