When developing the range of PDCS three-phase decanters for processing crude palm oil Peony focused on efficient, reliable separation of liquid, dry solids (cake) and oil for maximum oil recovery with minimum oil losses. The PDC range includes decanters suitable for every size of oil mill, from 30 to approximately 90 tons of fresh fruit bunches (FFB) per hour, and for a variety of crude palm oil applications including:

• Combined clarification and purification of pressed oil as part of the Peony all-in-one process (no need for settling tanks and dilution water), providing high oil recovery with low water consumption and effluent level.

• Sludge treatment after separation of diluted palm oil in settling tanks, using the three-phase decanter as an alternative to a nozzle separator. The decanter efficiently separates the slurry into oil, water and solid cake phases.

• Oil recovery from empty fruit bunch liquor (EFBL) immediately after pressing. After separation and removal of impurities with a decenter, the recovered high quality palm oil can be mixed with the freshly pressed oil.

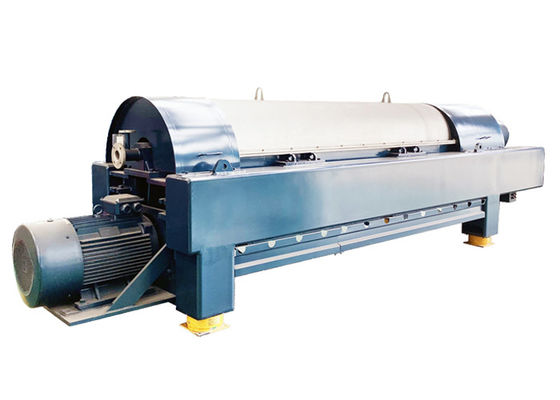

![]()

Specifications

|

Model |

Drum |

Power |

|||

|

Diameter |

Speed |

Length |

Length-to-diameter rate |

||

|

PDCS-16 |

400 |

3000 |

1400 |

3.5 |

45/15 |

|

PDCS-18 |

450 |

3200 |

2000 |

4.44 |

30/11 |

|

PDCS-20 |

500 |

3000 |

2000 |

4 |

37/11 |

Competitive Advantages

Picture

![]()

![]()